Introducing the 1,200 sf OMD prefabADU®

An expertly designed modular home built from three precision-engineered modules. Optimized for modern living, it balances elegance, efficiency, and environmental responsibility, with every square foot crafted for comfort and style.

Live Perfectly Proportioned.

This 1,200-square-foot accessory dwelling unit (ADU) in Los Angeles demonstrates how modular construction, fire-resistant design, and sustainable materials can work together to deliver a secure and modern living environment. Engineered as a flexible and energy-efficient residential solution, this prefab ADU combines off-site fabrication with site-specific strategies to respond to California’s evolving climate and housing needs.

Anchored by a vaulted butterfly roof and 12-foot interior ceilings, the two-bedroom, two-bathroom home balances spaciousness with ease of living. Its design updates traditional principles of simplicity and utility through contemporary modular construction, offering a refined, durable model for urban infill and multi-generational living.

Sustainability & Material Integrity

The material palette is guided by sustainability and resilience. Engineered wood, steel, and high-performance glazing form a durable building envelope, while interior finishes are chosen for longevity, low-VOC emissions, and aesthetic warmth. The result demonstrates that environmental responsibility and design excellence are not mutually exclusive.

Site Integration

The home responds to its landscape context by leveraging natural topography, prevailing winds, and solar orientation. Outdoor areas are framed as extensions of the living environment, establishing a strong relationship between interior and exterior while maximizing comfort and energy efficiency.

Innovation & Resilience

Fire resilience is embedded throughout the design—from exterior cladding to strategic setbacks and defensible landscaping. House-hardening strategies include ember-protected detailing and fire-resistant materials. Modular construction further enhances resilience by reducing on-site risk, accelerating delivery, and allowing flexibility for future maintenance or expansion.

Modular Fabrication

The home is composed of four modules, prefabricated in a controlled local factory in Southern California. While the modules are assembled off-site, foundations and utilities are completed in parallel, reducing construction time by one-third. This process minimizes waste, optimizes labor, and avoids the disruption associated with conventional on-site building.

“For 20 years, Los Angeles designer and professor Jennifer Siegal has been pushing the limits of modular housing through her firm OMD, most recently with a series of prefab accessory dwelling units just released this fall.” -Dwell magazine, one last thing

Our prefabADU® can be established on properties where there is an existing or proposed primary single-family residence. We provide homeowners with rental income and additional space for family members or caregivers. Each of our three turn-key models includes kitchen, bathroom, bedroom, living room and laundry. Built in California, our smart homes meet the highest national energy efficiency standards.

Our designs are inspired by the Shakers who believed in quality, integrity and reliability.

Our ADU Collection

Our Partners

Bryan Henson, President and CEO of bevyhouse

Prefab Manufacturer and Site Work Partner:

Bevyhouse believes that high quality housing should be accessible to everyone. Their vision is to make designing and building a home easier than it has ever been before by reimagining how dwellings are designed and constructed. Bryan Henson heads up Bevyhouse and is a nationally recognized leader in the custom residential world. He grew his former company, Allen Construction, to one of the top five remodeling companies in the US. Bryan is passionate about sustainable, healthy homes and has been a guest speaker for Dwell magazine, has taught masters level courses on sustainable design, and has personally overseen multiple LEED platinum and passive house certified projects.

Takuhiro Shinomoto, Co-Owner of Tortoise

Premium Kitchen Design Partner:

Following 13 years as an in-house furniture designer for Idée in Tokyo, Japan, Taku Shinomoto moved to the US in 2003 with his wife Keiko and opened Tortoise in Venice, California. Tortoise has dedicated itself to introducing timeless Japanese home goods with a story and exhibiting works by contemporary Japanese artists, guided by the store's basic philosophy of a slow and stead life. Taku is most well known for his work as designer of the Hasami Porcelain Series, which now has worldwide circulation.

OMD’s Experience

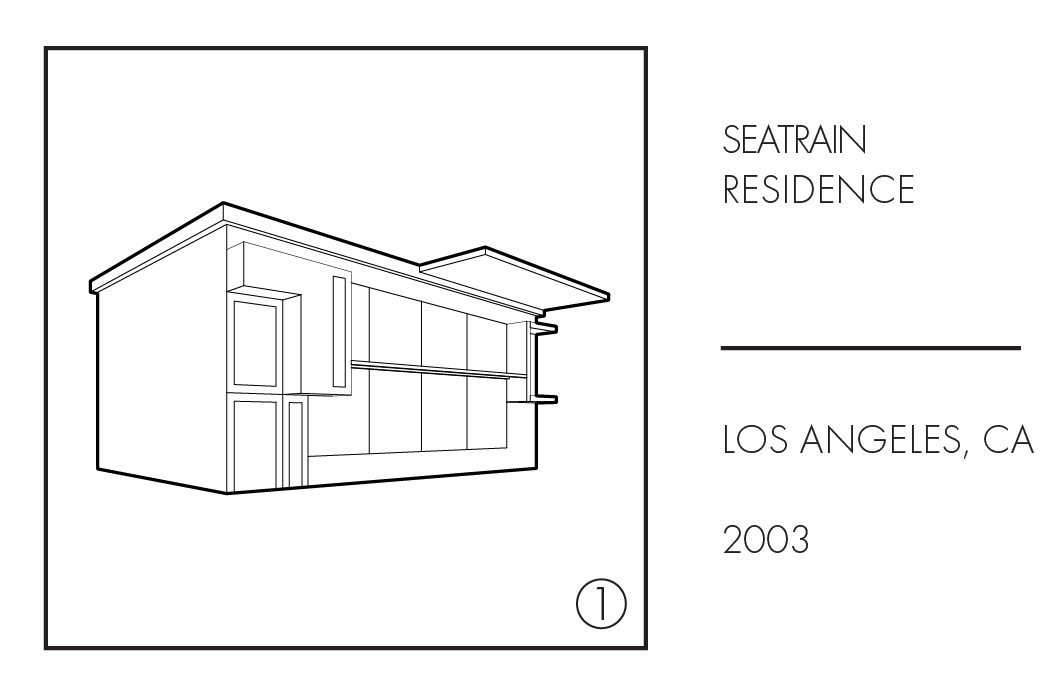

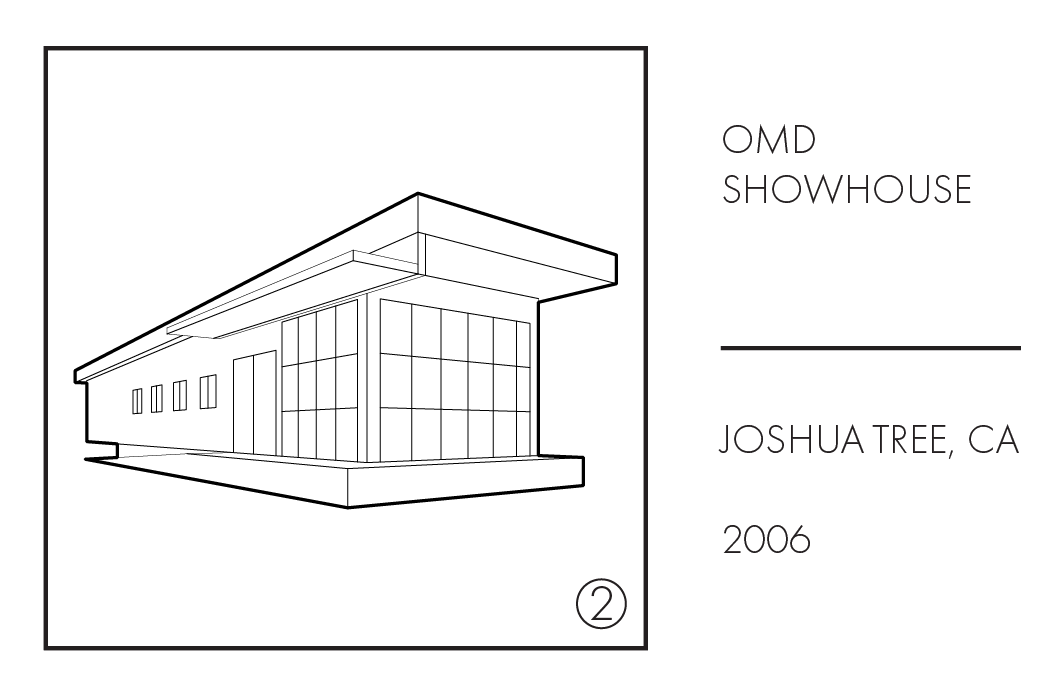

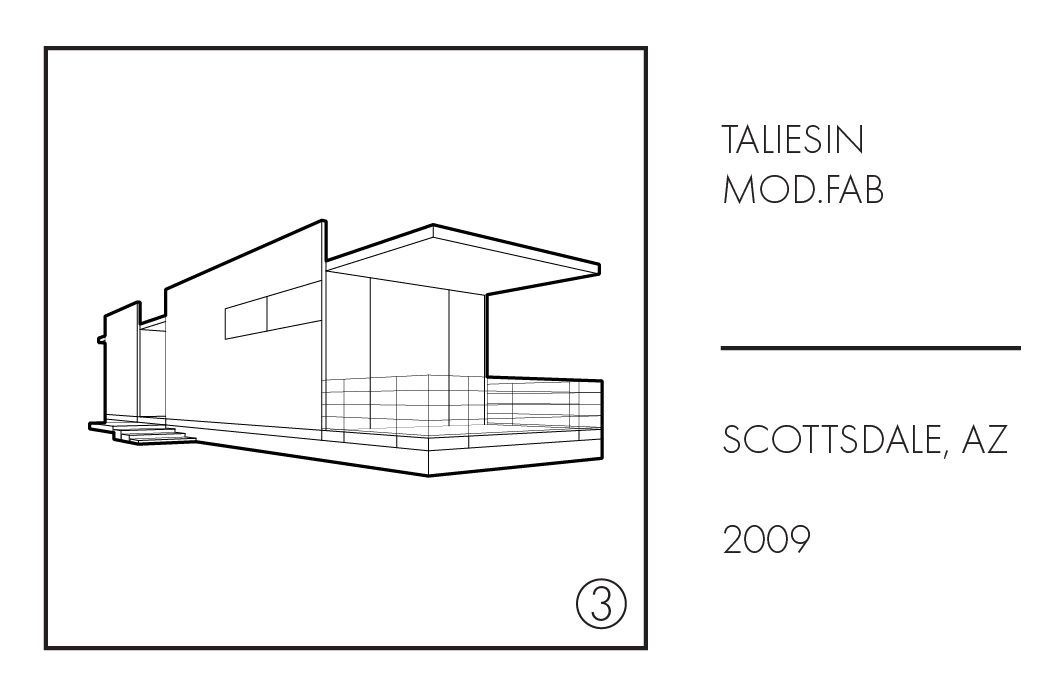

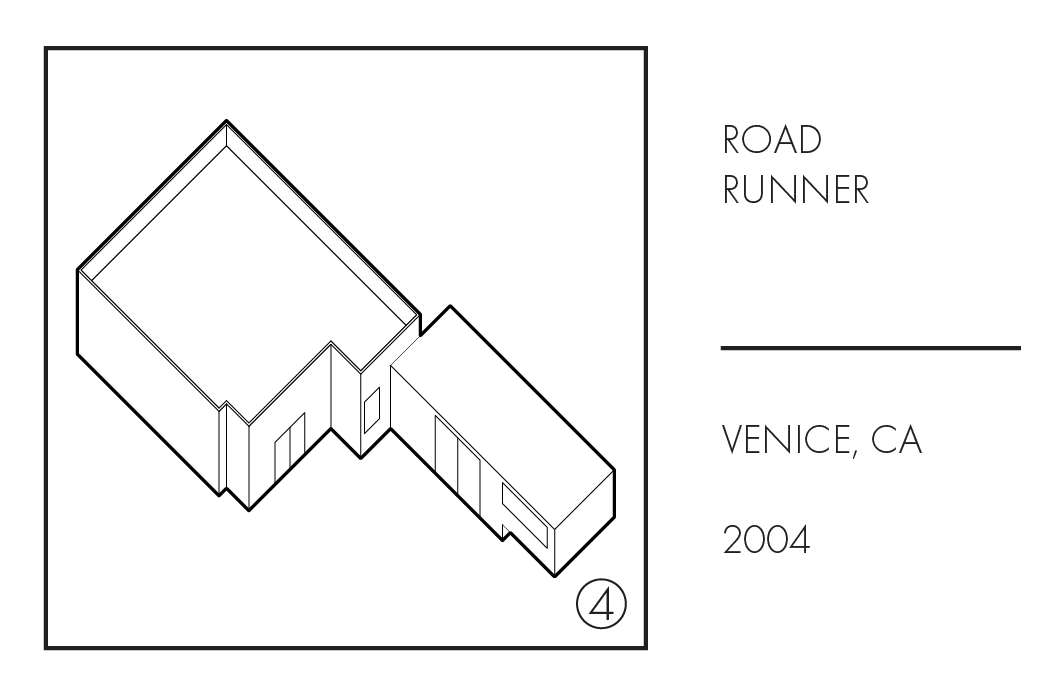

Jennifer Siegal is known for her work in creating the mobile home of the 21st century. She is founder and principal of the Los Angeles-based Office of Mobile Design (OMD), which is dedicated to the design and construction of ecologically sound, dynamic structures, utilizing portable and prefabricated architecture. Founded in 1998, OMD is distinguished as the leader in the field with award winning prefab projects and a commitment to sustainable design. The international arcVision Prize- Women and Architecture recipient, Siegal was unanimously chosen by the jury for being “a fearless pioneer in the research and development of prefabricated construction systems.”

1. Six modules-3000 sf custom residence composed of 2 pairs of stacked ISO shipping containers and 2 grain trailers sheltered under a 50 ft steel and glass roof membrane

2. One module-720 sf prefabricated modular Showroom

3. One module-960 sf prefabricated modular house

4. One module-200 sf ‘drop frame’ moving trailer addition to existing 1920’s California bungalow

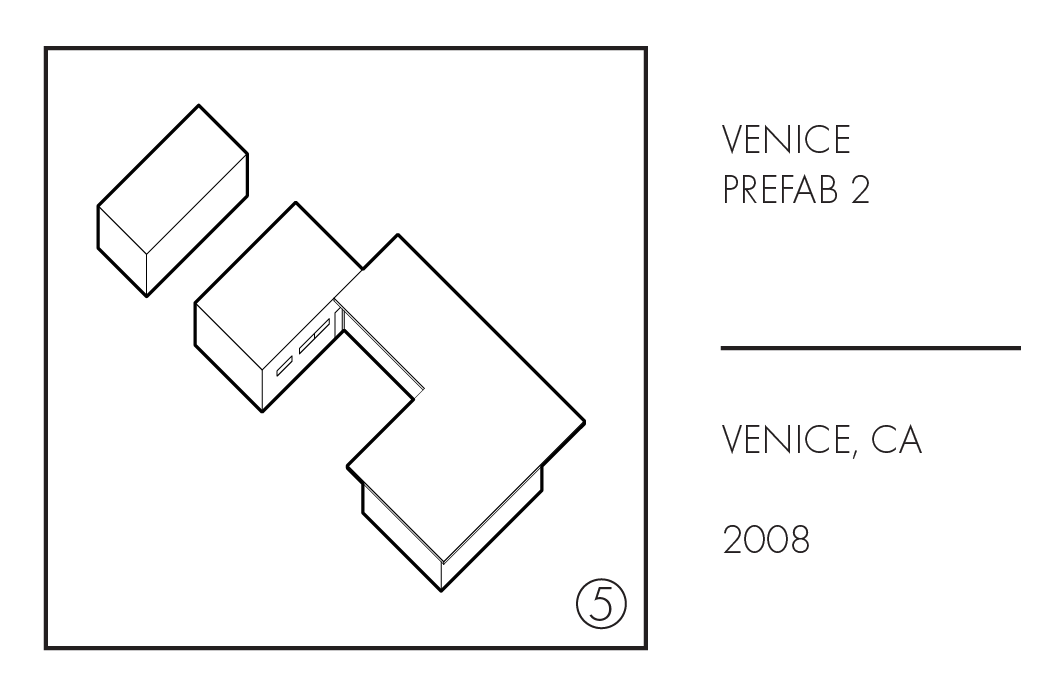

5. Four modules-3280 sf prefabricated modular house

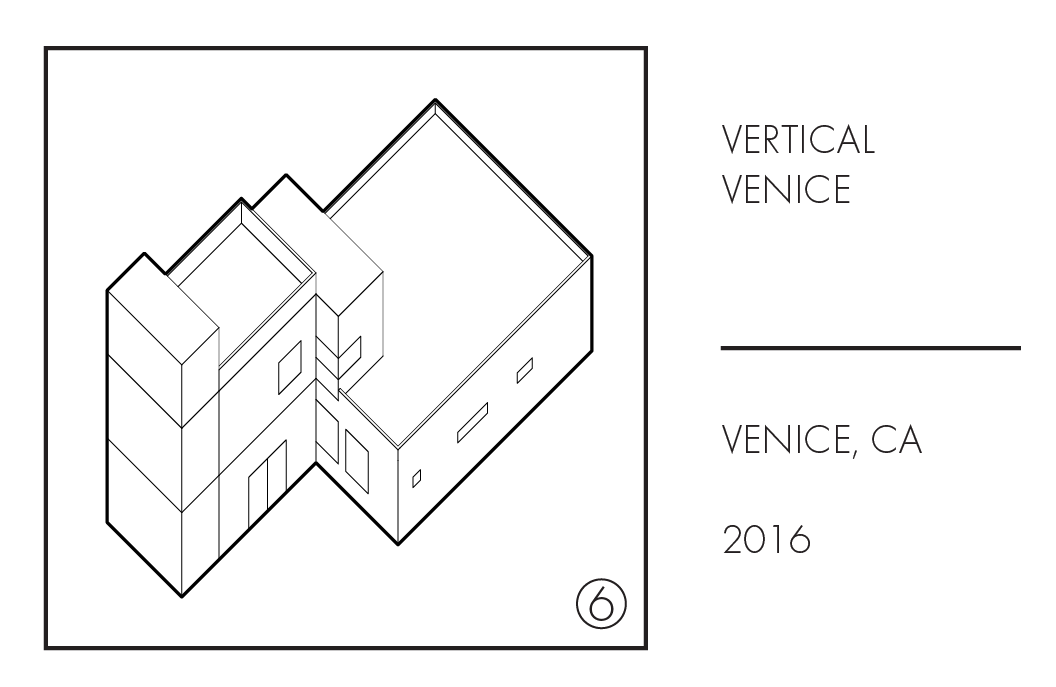

6. Three modules-1850 sf prefabricated modular and site-built addition to existing single-family bungalow